Summary this paper presents the results of an experimental study of heat transfer characteristics in single phase and two phase stagnation point flows pertinent to quenching of glass in the temperi.

Quenching glass ceramic.

With the increase of the er3 doping.

The thermal quenching of fluorescence of ce y 3 al 5 o 12 glass ceramic yag gc phosphor was evaluated and compared with those of ce y 3 al 5 o 12 polycrystal yag pc and ce gd y 3 al 5 o 12 glass ceramic gdyag.

Glass ceramic materials share many properties with both glasses and ceramics glass ceramics have an amorphous phase and one or more crystalline phases and are produced by a so called controlled crystallization in contrast to a spontaneous crystallization which is usually not wanted in.

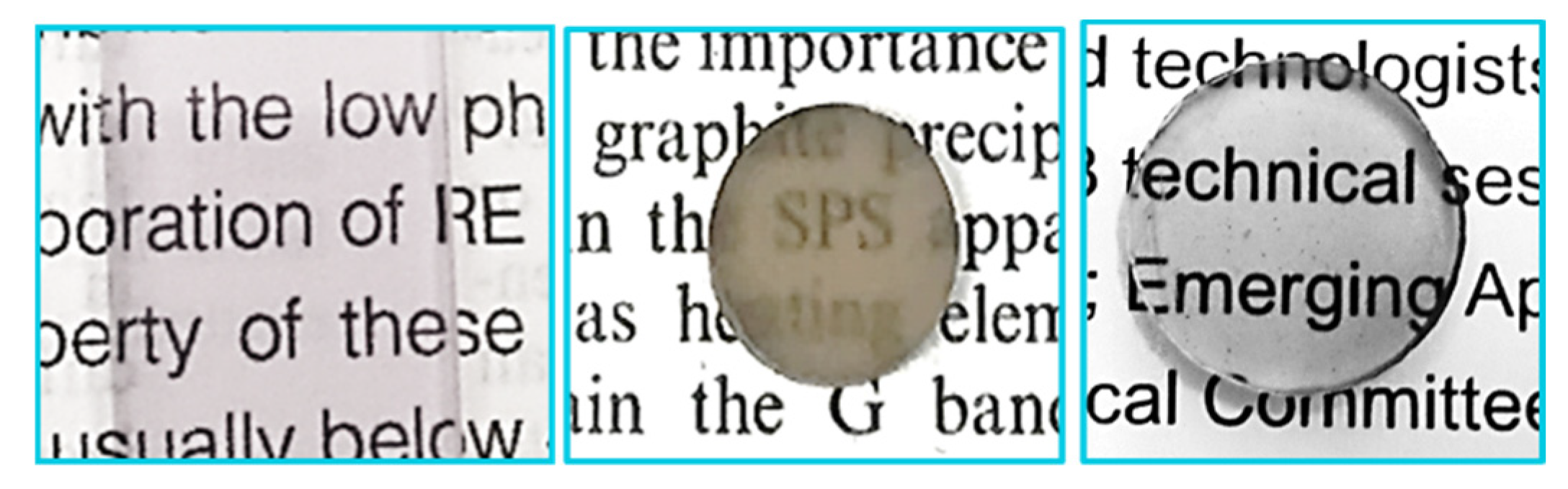

Glass ceramics are polycrystalline materials produced through controlled crystallization of base glass.

The feasibility to immobilize the hlw by monazite iron phosphate glass ceramics is discussed.

In this work we have studied the concentration quenching in transparent glass ceramics containing er3 nayf4 nanocrystals.

The glass referenced as cel2 was prepared by a traditional melting quenching process.

The glass reagents high purity powders of sio 2 ca 3 po 4 2 caco 3 mgco 3 4 mg oh 2 5h 2 o na 2 co 3 and k 2 co 3 1.

Glass ceramics with nanocrystals present a transparency higher than that expected from the theory of rayleigh scattering.

For different concentrations the emission spectra and decay curves of the 4i13 2 4i15 2 emission were measured.

Quenching effect will be there on both physical and structural properties.

Ce la nd po 4 phosphate based glass ceramics are potential candidates for the hlw.

The er concentration dependence of integrated intensity and lifetime of 4i13 2 4i15 2 emission are showed.

Monazite iron phosphate glass ceramic wasteforms were prepared by a melt quenching process.